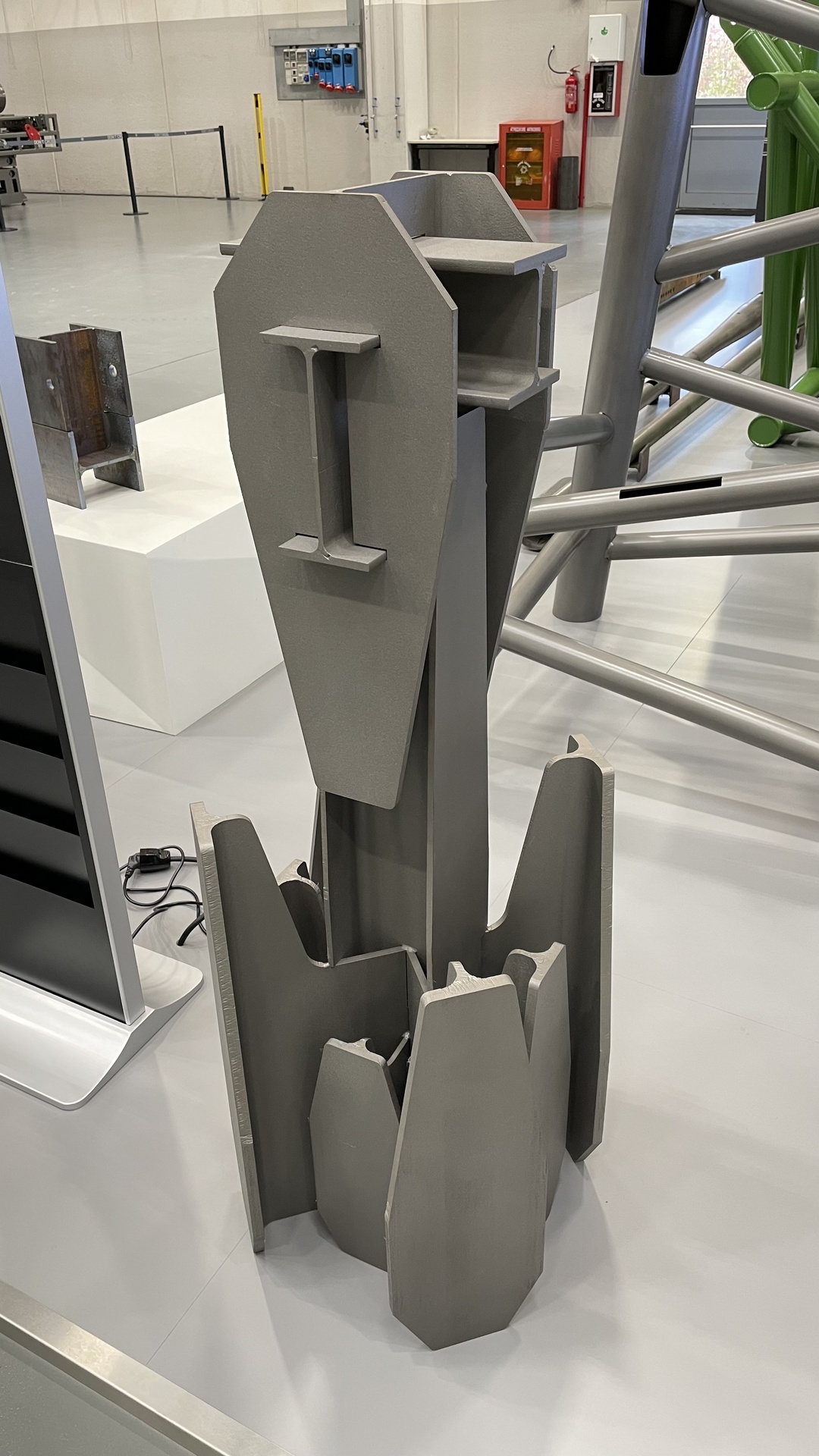

Solar FM, is a family-owned business that was founded by Mr. Peter Lakics in Komló, South-Western Hungary as a sister company of Solar Construction (http://solarconstruction.hu). Our main activities are the planning and production of semi-finished and finished metal products and the construction of bigger-scale steel structures. Our profile includes the whole planning and manufacturing process from the preparation of the technical documentation to construction and logistics.

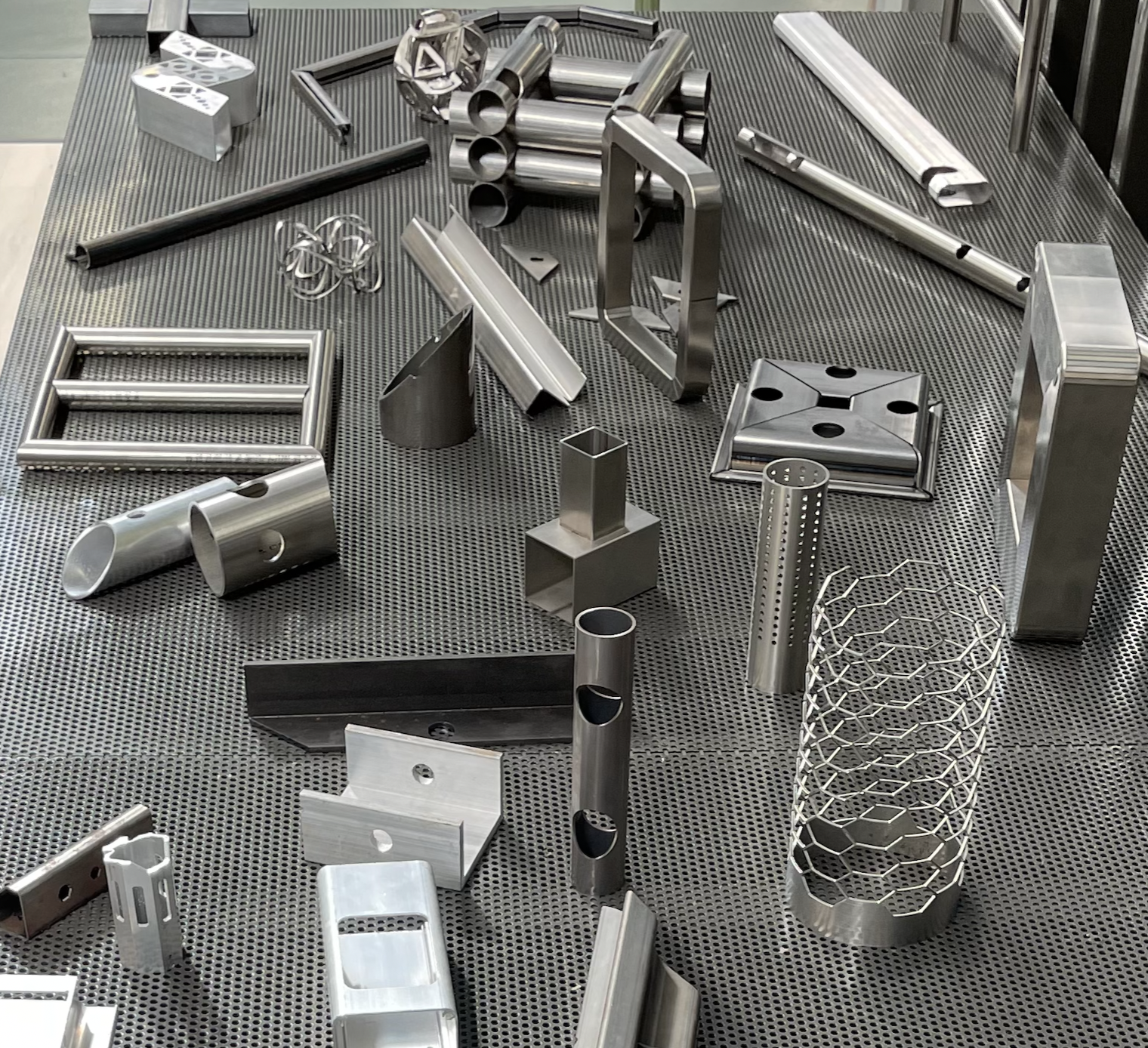

Laser cutting is the core technology of our sheet metal fabrication company located in Komló, close to Pécs.

In the field of laser cutting we know all what there is to know as our specialists have many years of experience in steel machining technology. The technical level of machinery and the skills of professionals allow to serve the needs of middle-size and large corporate companies at an outstanding level.

Along with the development of other sheet metal technologies there has been a huge development in laser cutting in the last decade. However, the efficiency and flexibility of laser cutting is still outstanding. The technological background based on modern machinery (CO2 and fiber laser) enables us to manufacture medium and large series of sheet and profile metal parts. The accuracy and precision are those expectations to which we are able to meet.

For us, building steel structures is not only a mission, but also an art and a passion.